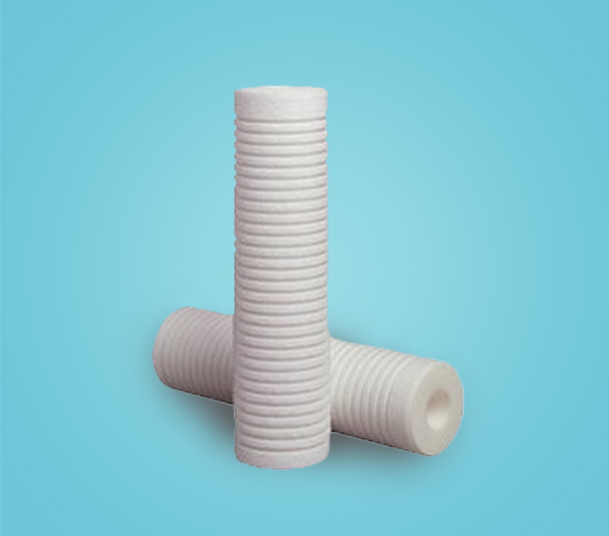

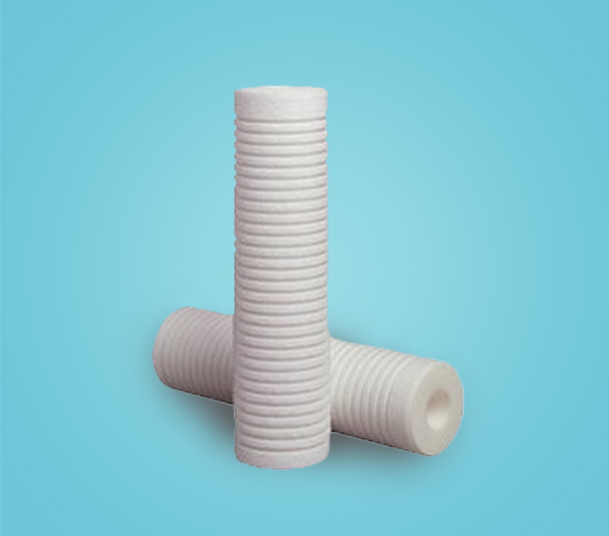

Trinity Pure-BOND Resin-bonded cartridge filters

Trinity Pure-BOND

Resin Bonded Filter Cartridges

feature an advanced manufacturing process that produces a

rigid graded density structure that allows the filter to withstand extreme viscosity and temperatures without deformation or collapse.

The true graded density of Resin Bonded Filter Cartridges configuration allows complete utilization of the filter depth, with larger particles captured in the outer zone

and finer particles trapped in the inner qualifying zone. The grooved design of

Resin Bonded Filters

increases the surface area of the filter hence reducing the

clean differential pressure and increasing the dirt holding capacity of the filter. The rigid construction of Resin Bonded Filter Cartridges ensures consistency, reproducible

performance free from bye-pass and unloading.

-

Grooved outer surface increases surface area for extended service life.

-

Rigid structure designed to handle high differential pressure and can be used for high viscosity applications.

-

High voids volume ensures better dirt holding capacity resulting in longer service life.

-

Available in a wide range of removal ratings from 0.2 to 150 micron.

-

Two different types of Fibers & Resins (Acrylic Phenolic & Cellulose Melamine) for use in Industrial and pharmaceuticals / Food & Beverages Applications respectively.

-

No Metal/ plastic cores for easy disposal.

-

Broad chemical compatibility.